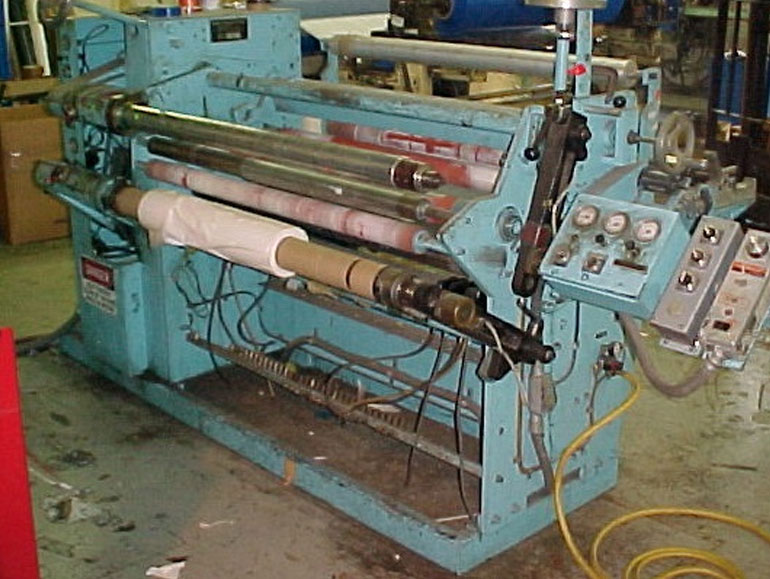

The range between new machinery and used slitter/rewinders is dramatic. Depending upon the application, the allotted budget may be be exceeded by procuring a new piece built to specification with all the desired features. At the other end of the spectrum, searching on the lower end of the used market affords little flexibility in machine condition, quality, type and features. Such a situation introduces the opportunity for a rebuilt/ upgraded unit.

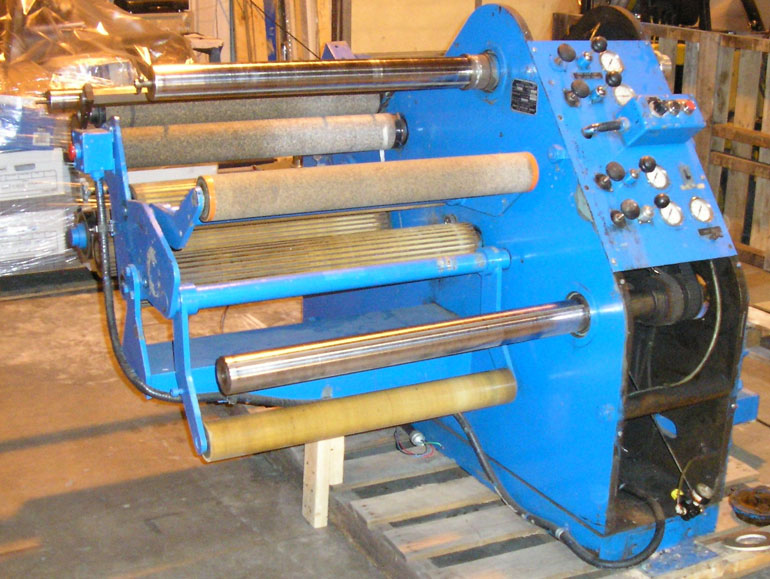

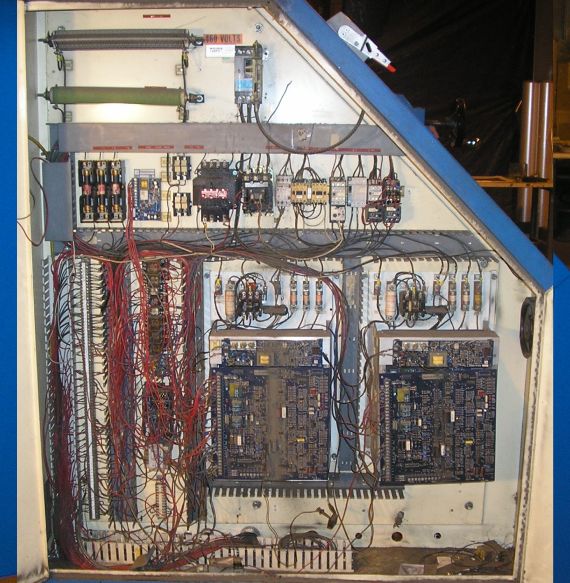

You may have an old unit that has been utilized for many years but spends more time under repair than in production.

There may be a need for additional capacity and a used slitter/rewinder has been procured but requires much attention.

Phoenix can help.

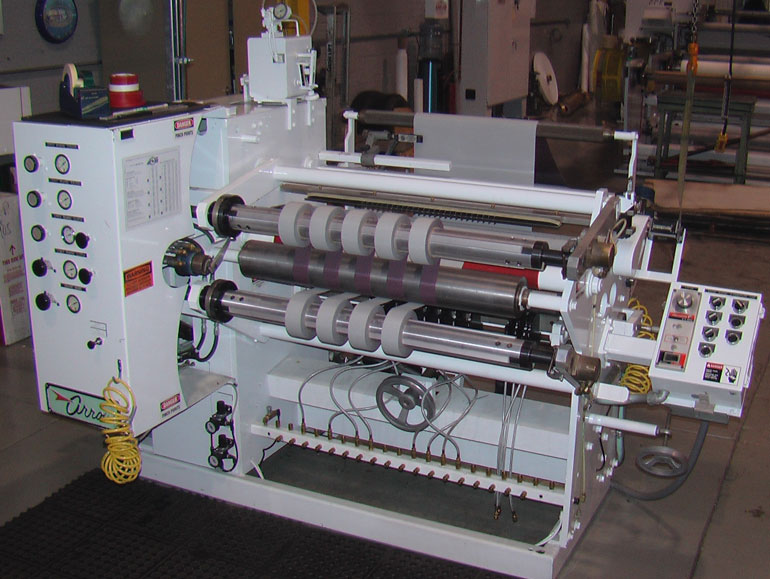

A typical Phoenix rebuild Includes:

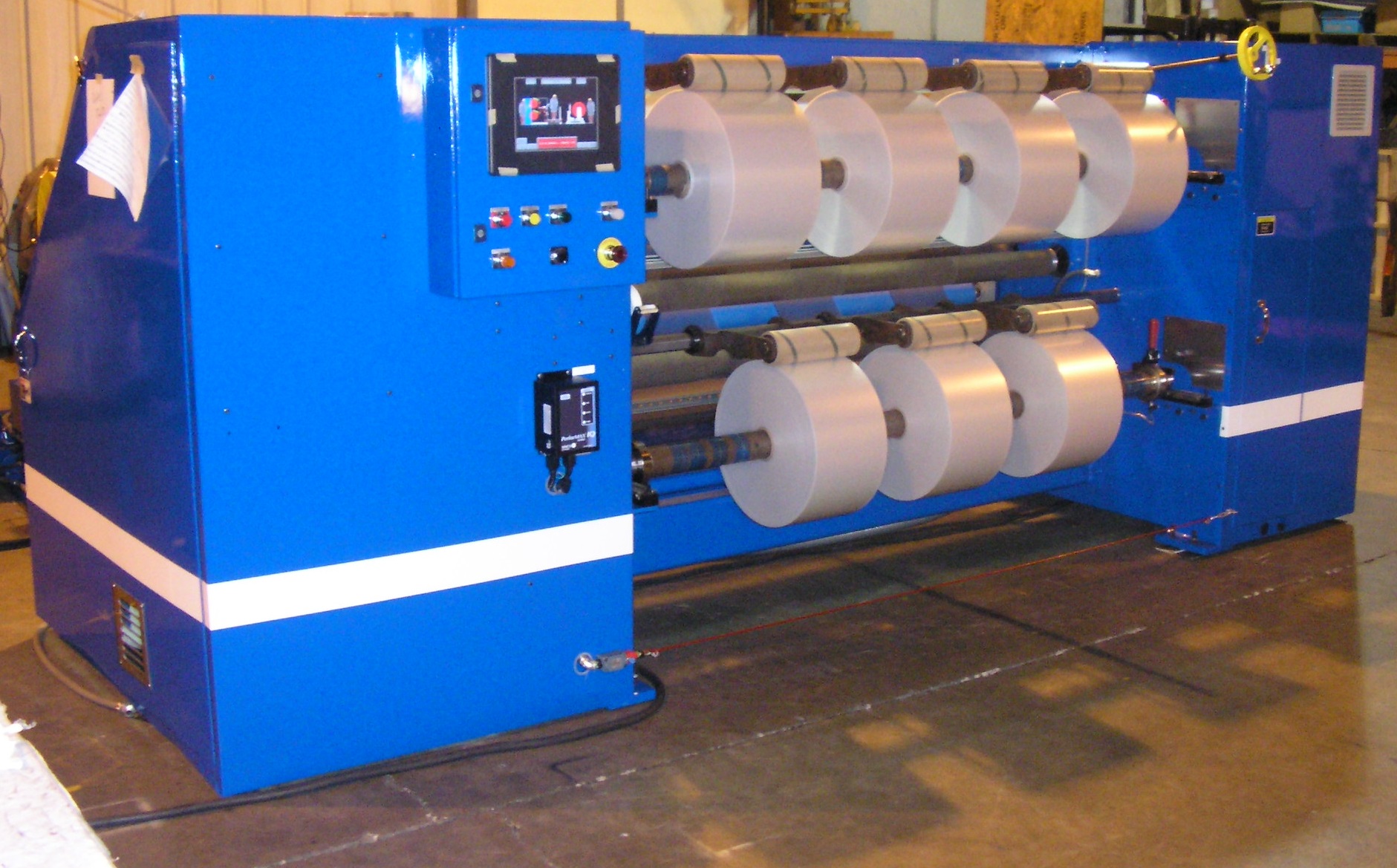

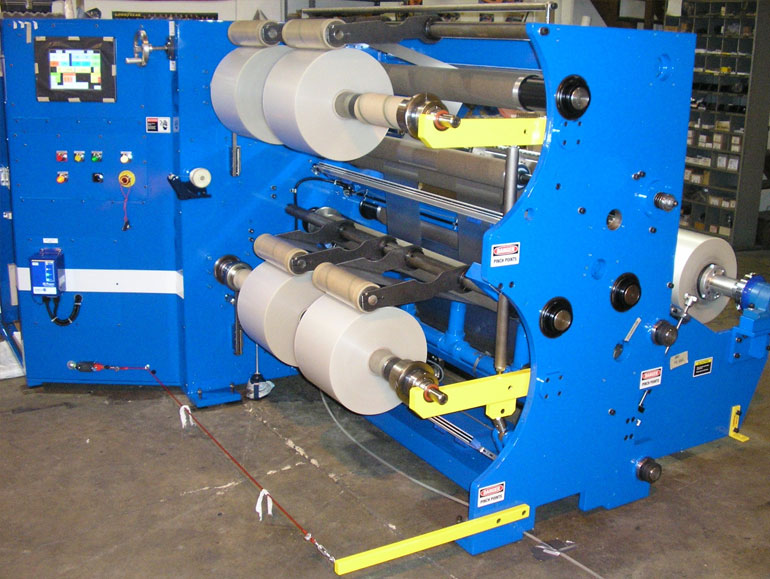

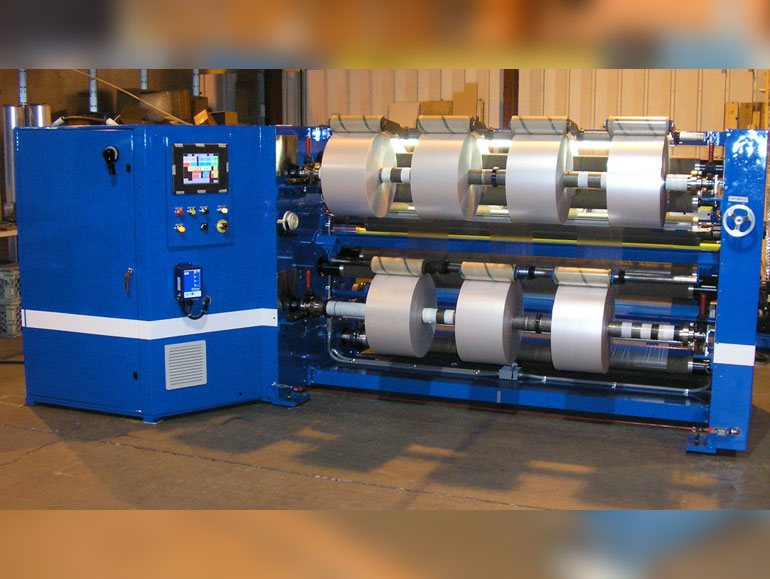

Converting lift out machines to cantilevered units, upgrading single to multi-motor drive systems with recipe storage HMI, adding automatic tension control, spacer-less differential rewind mandrels, roll handling features, adding larger capacity unwinds and additional slitting styles are easily accomplished. Most feature upgrades and options that are available for new Phoenix machinery can be offered on all rebuilt projects.

As with new Phoenix machinery, all rebuilt units are tested by Phoenix on our factory floor and run through a factory acceptance test with the buyer prior to shipping.

For added peace of mind a standard warranty covers all replaced parts, and our service department is available for installation supervision, operator and maintenance training, and after-sale support.

Please contact Phoenix to discuss rebuilding as an alternative.