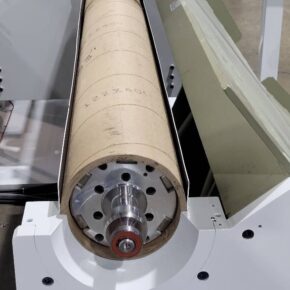

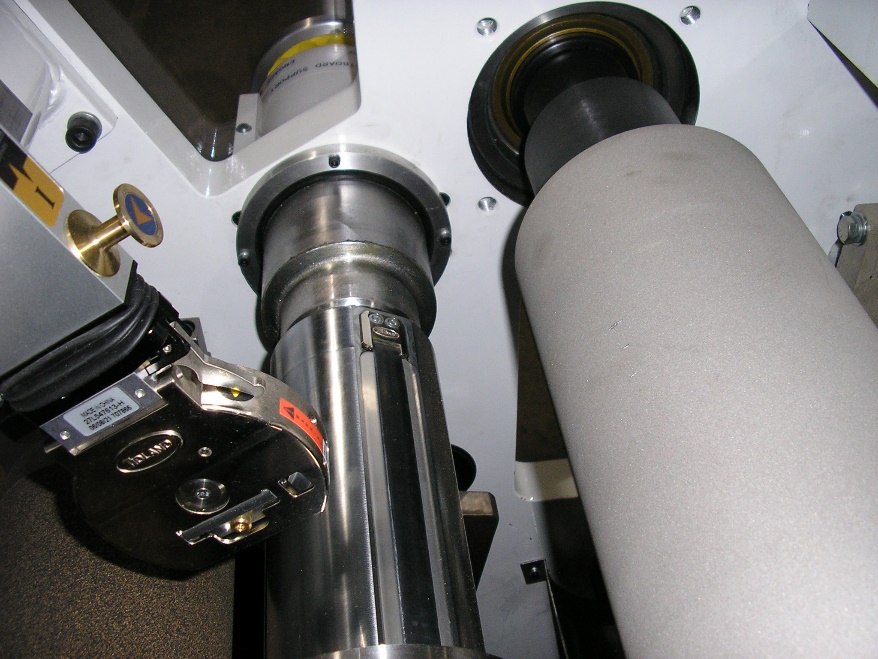

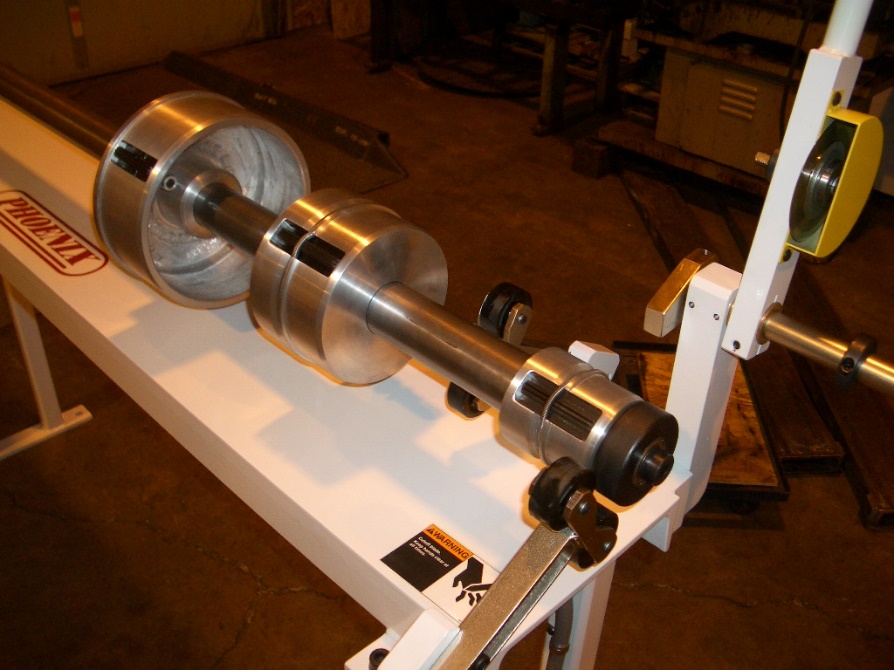

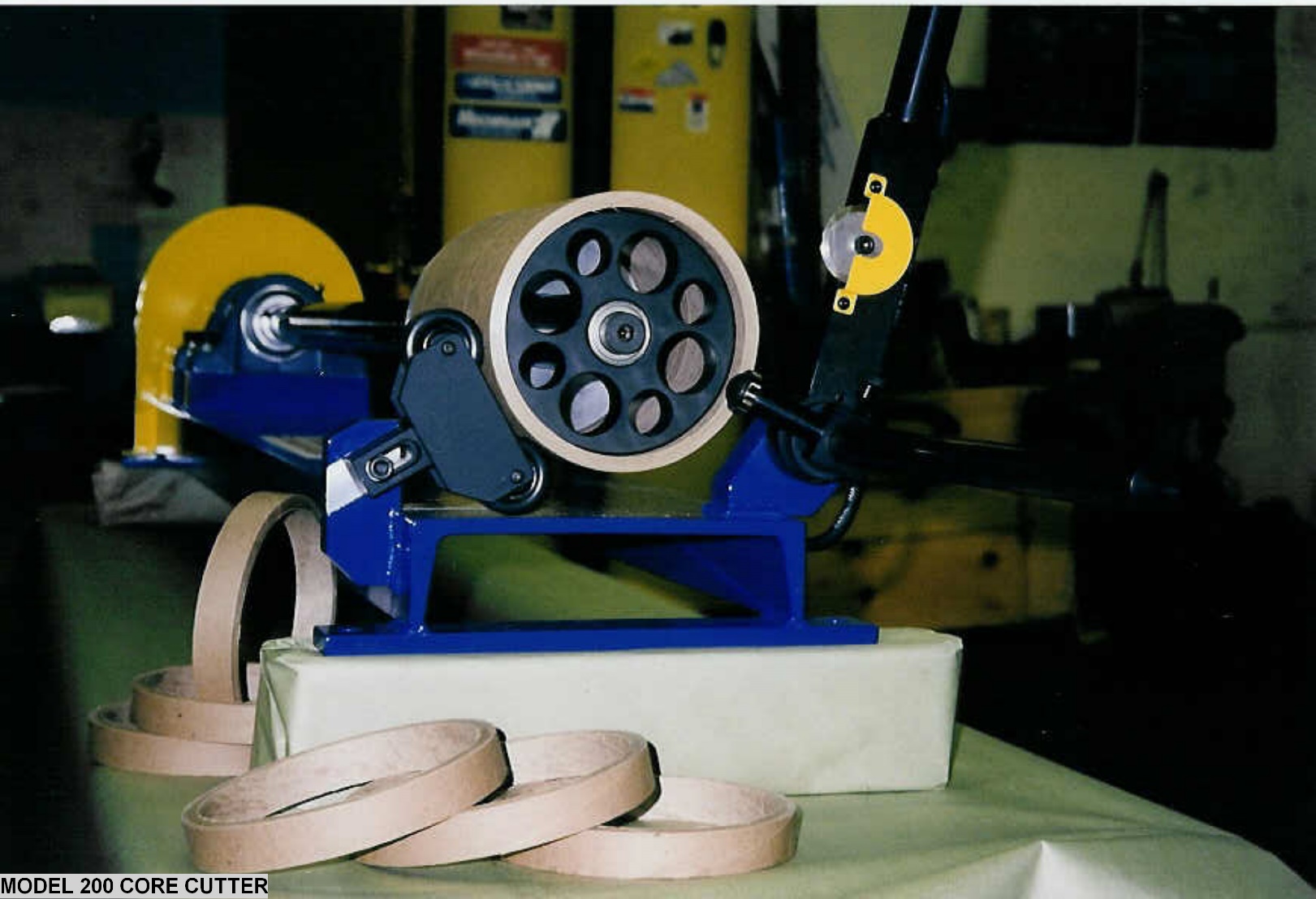

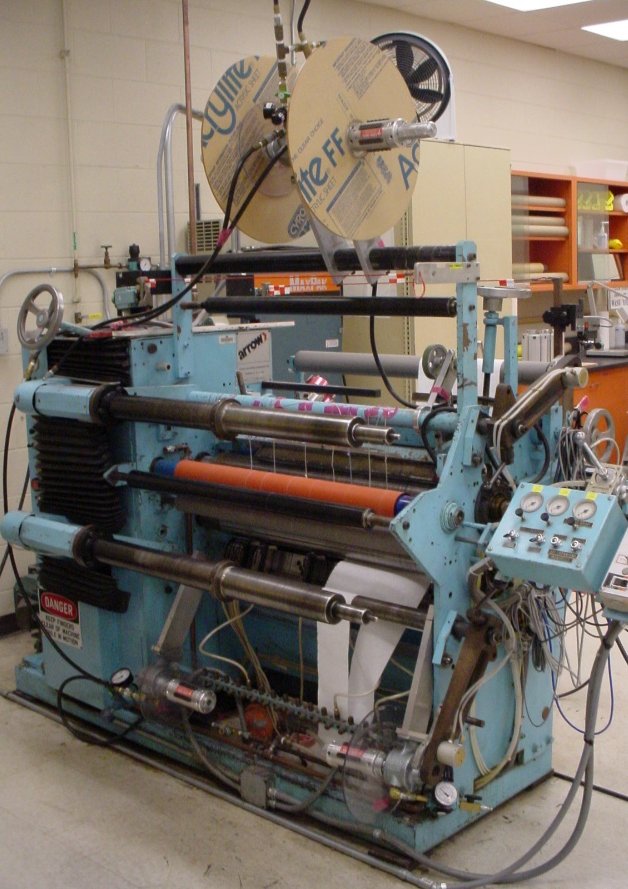

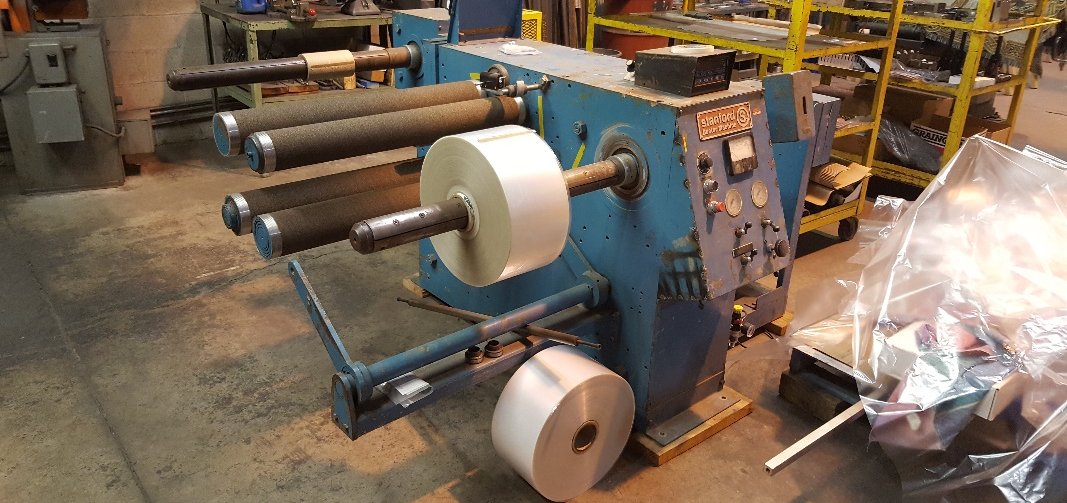

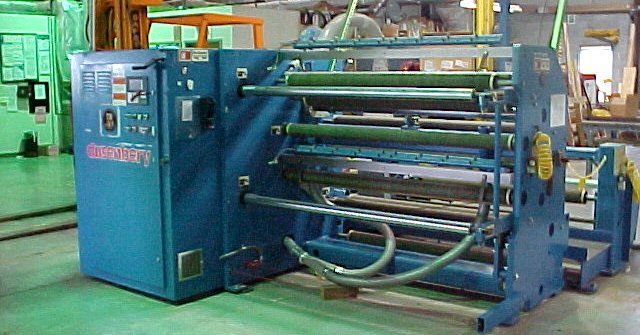

Machine upgrades, accessories and options are almost limitless and can be provided on every new Phoenix Machine project, rebuild, or in-use production machine.

Changes are accomplished at our facility in Flanders, NJ or in the field for existing units.

Upgrades can be performed on any converting machinery manufacturer’s unit, with the Phoenix design staff engineering changes from field recorded measurements and installation completed by our mechanical and electrical technicians for a total turn-key package.

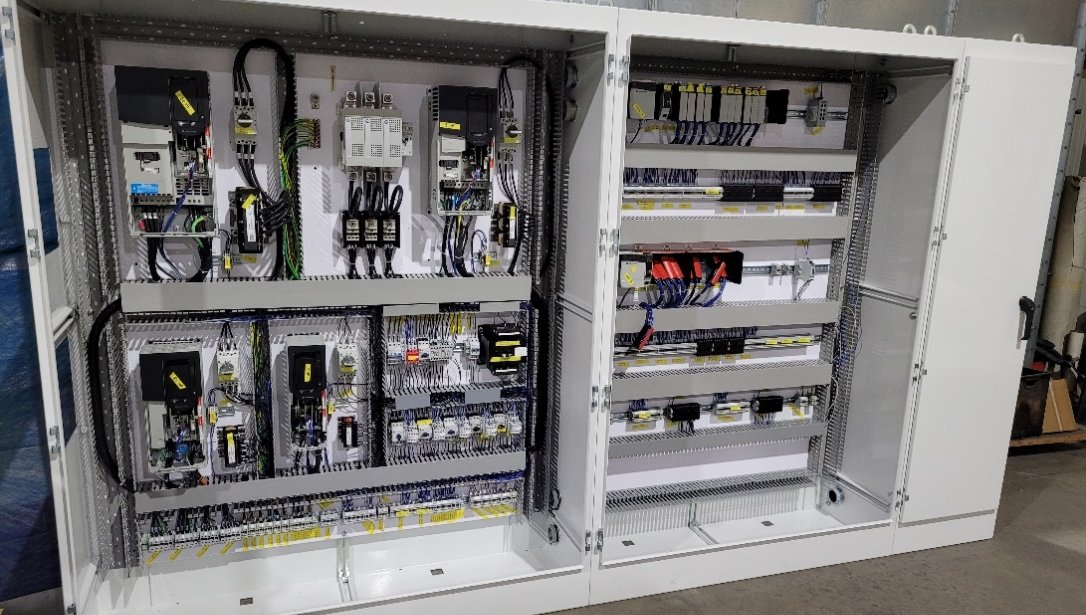

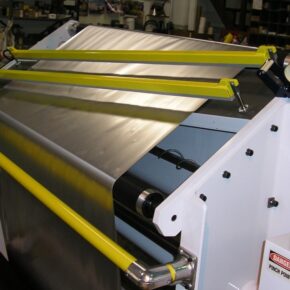

Some common upgrades include new drive packages (single to multi-motor transmission), touchscreen recipe storage (HMI), ergonomic roll handing adders, additional slitting types, closed and open loop tension control systems and operator safety upgrades.

Phoenix also offers used machines for sale, “as is” (if in acceptable condition) or rebuilt, to the general converting marketplace. Speaking with a Phoenix Sales Engineer allows the discussion of your primary needs, possible future requirements, and general overall concerns to offer the perfect solution for your converting application.

Whether it be new machinery, a rebuilt unit, used machine or an upgrade to an existing system, Phoenix can handle it!