Slitting is a crucial process in converting materials such as films, tapes, foils, and non-wovens. The choice of slitting technique directly affects product quality, material waste, and overall efficiency. In this article, we will explore the three main types of slitting methods used in Slitter Rewinder machines: score slitting, shear slitting, and razor slitting. By understanding the differences and applications of each technique, you can make informed decisions when selecting the right web handling equipment for your business.

The Importance of Choosing the Right Slitting Method

Slitting is not a one-size-fits-all process. The right technique depends on the type of material, desired edge quality, and production speed. Whether you are working with film slitter rewinders, tape slitting machines, or nonwoven slitters, selecting the correct method ensures precision and efficiency.

Score Slitting: Simple and Effective

What is Score Slitting?

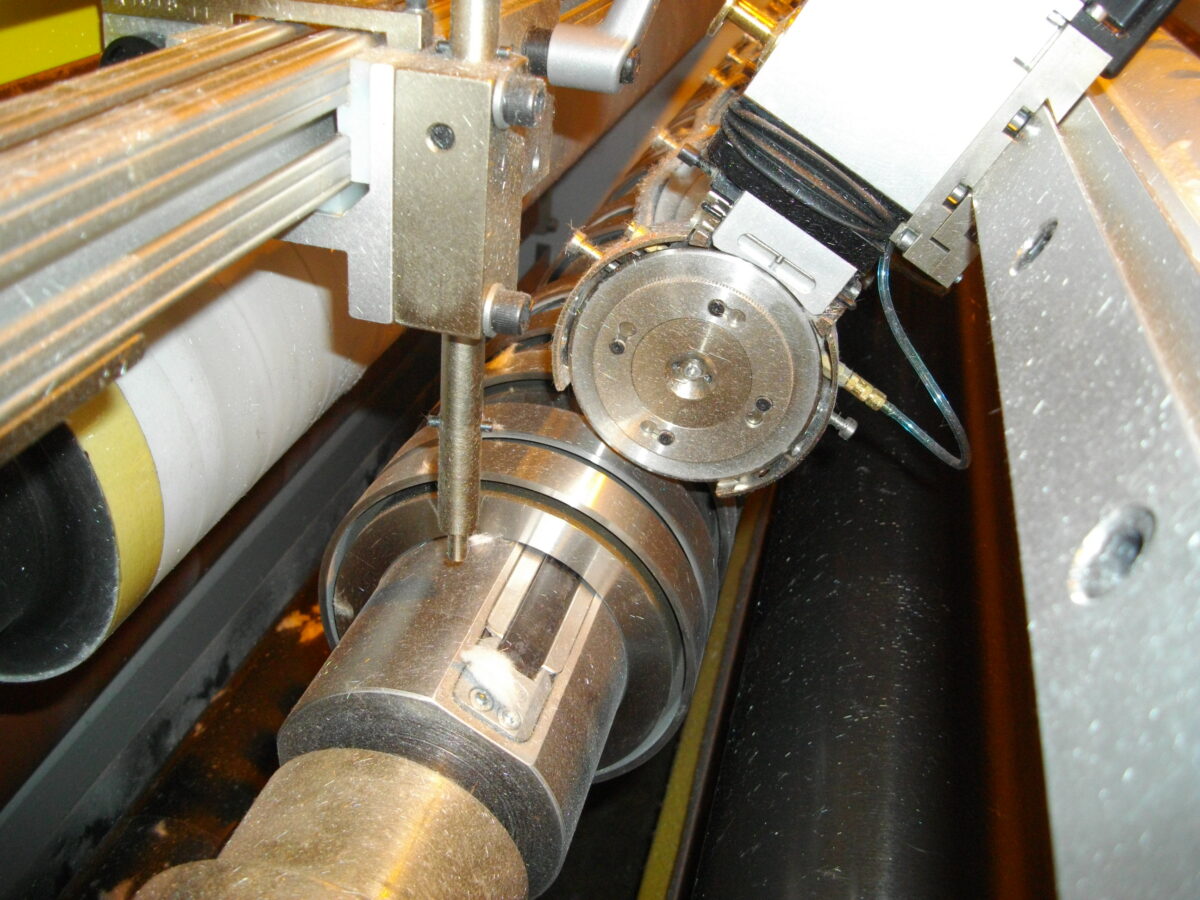

Score slitting, also known as crush cutting, involves pressing a circular blade against a hard anvil roll to cut the material. The pressure applied crushes the material against the roller, creating a slit.

Applications of Score Slitting

- Ideal for board stock, nonwoven materials, foams, thick films and tapes

- Commonly available on all types of Slitter Rewinders

- Available in Automatic Knife Positioner systems

Advantages

- Simple design and operation

- Effective for thicker materials

- Cost-efficient with minimal maintenance requirements

Disadvantages

- Not suitable for thin or delicate materials

- Can cause deformation in certain substrates

Shear Slitting: Precision Cutting

What is Shear Slitting?

Shear slitting involves two rotary blades that function like scissors to cut through the material. This method provides a clean, precise edge and is commonly used in label converting, laminate converting and paper converting where edge cut quality and slit tolerances are important.

Applications of Shear Slitting

- Best for paper, films, foils, and laminates

- Commonly available on all types of Slitter Rewinders

- Available in Automatic Knife Positioner systems

Advantages

- Produces clean, high-quality edges

- Reduces dust and material waste

- Ideal for high-speed applications

Disadvantages

- Requires precise blade alignment

- Regular maintenance needed for optimal performance

- High initial investment

Razor Slitting: Perfect for Thin Materials

What is Razor Slitting?

Razor slitting uses a sharp razor blade positioned above the material to slice through it. This method is commonly found in film Slitter Rewinders and flexible packaging slitting machines.

Applications of Razor Slitting

- Best for thin films, foils, and lightweight materials

- Commonly available on all types of Slitter Rewinders

- Available in Automatic Knife Positioner systems

Advantages

- Simple and cost-effective

- Minimal material distortion

- Works well for fragile materials

Disadvantages

- Blades wear out quickly and require frequent replacement

- Limited to certain material types

Selecting the Best Slitting Technique for Your Needs

When deciding which slitting method to use, consider the following factors:

- Material Thickness: Thin materials work best with razor slitters, while thicker materials are better suited for score slitters.

- Edge Quality: If precision edges are required, shear slitting is the ideal choice.

- Production Speed: High-speed applications typically use shear slitting for efficiency.

- Maintenance Needs: Score and razor slitters have lower maintenance demands compared to shear slitters.

Understanding the differences between score slitting, shear slitting, and razor slitting is essential for optimizing your converting equipment. Whether you’re investing in a new slitter rewinder or want to explore machine upgrading or rebuilding services, selecting the right slitting method will improve efficiency and product quality. If you’re looking for a Slitter Rewinder or need assistance with a converting equipment upgrade, contact a reputable manufacturer to discuss your options.

Looking for expert guidance on selecting or maintaining your Slitter Rewinder? Contact our team today to find the best Slitter Rewinder for your needs.