In high-volume converting operations, maximizing equipment efficiency is essential to maintaining throughput, reducing material waste, and ensuring consistent product quality. Surface winders serve as critical components in roll-to-roll processes, providing the foundation for effective material handling and finished roll formation. When engineered and operated properly, these machines significantly enhance overall line performance. This article presents a technical overview of key strategies to optimize surface winder efficiency, emphasizing performance reliability, operational longevity, and return on investment.

Enhancing Machine Performance

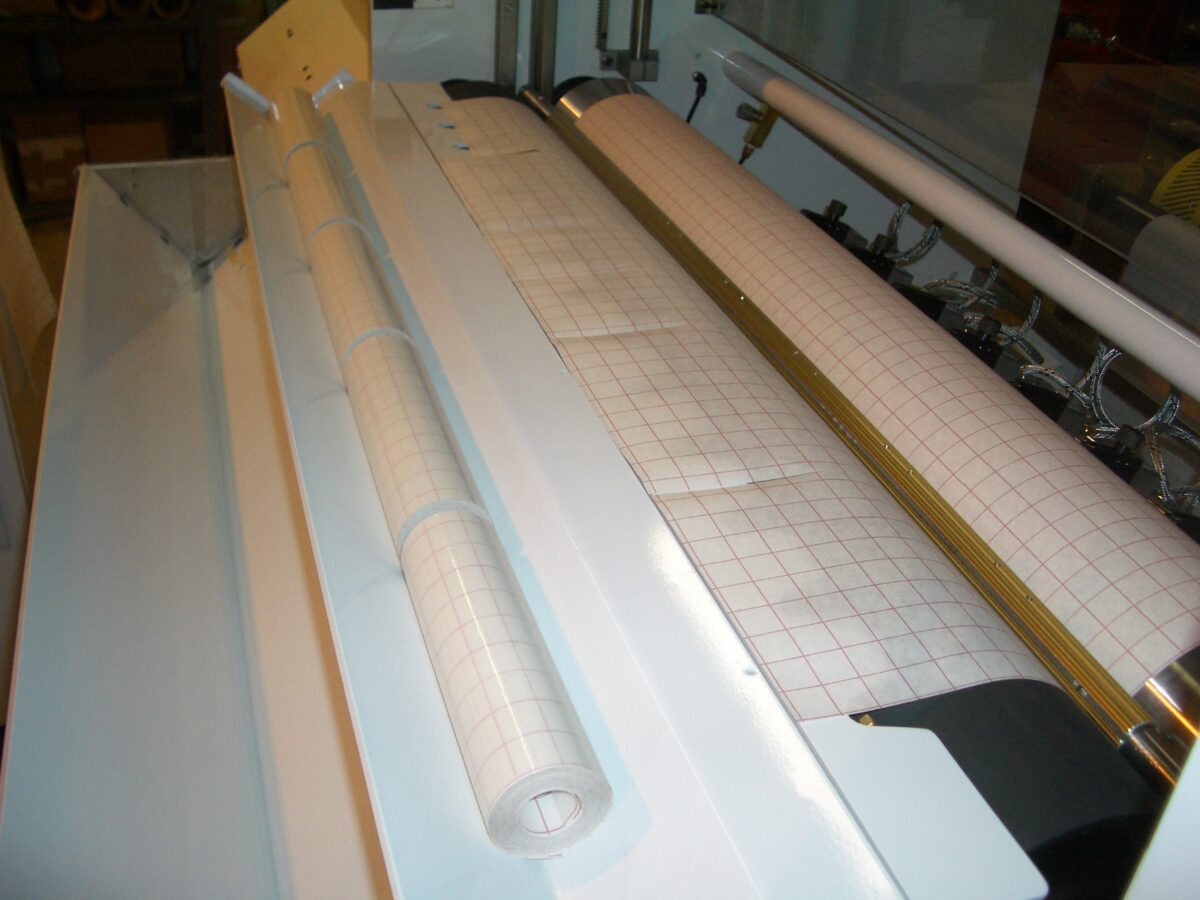

To fully leverage the capabilities of a surface winder, operators must focus on the integration and optimization of three key functions: material setup, slitting precision, and tension control. Proper material setup minimizes the risk of uneven winding, telescoping, or slack zones that could compromise roll integrity. Implementing guided web alignment systems helps maintain consistency, while inspecting materials for defects before processing can prevent costly errors. Ensuring materials are properly prepared before entering the surface winder reduces the risk of misalignment and poor roll formation.

Slitting accuracy plays a central role in ensuring downstream quality and production efficiency. The method of slitting must be selected based on substrate characteristics. Shear slitting, offering high-precision cuts with minimal material deformation, is ideal for denser or multilayered materials. In contrast, score slitting provides a controlled solution for softer substrates, balancing speed and cleanliness. Regardless of method, the performance of the slitting system is directly tied to blade condition; therefore, routine blade inspection and timely replacement are critical to preserving cut quality and preventing edge fraying or material distortion.

Controlling tension throughout the winding process is critical for producing high-quality rolls. Automatic tension control systems help maintain uniform roll formation by adjusting tension in real-time based on material type and thickness. Operators should routinely monitor tension levels to identify potential issues and make adjustments before defects occur. By implementing these best practices, businesses can significantly enhance the efficiency and performance of their surface winders.

Proactive Maintenance for Long-Term Reliability

Sustained surface winder performance depends not only on correct operation but also on disciplined maintenance practices. A proactive maintenance strategy—focusing on regular inspections, systematic lubrication, and preemptive part replacement—significantly reduces the likelihood of unexpected failures and preserves machine availability. Establishing a maintenance schedule aligned with operating hours or production cycles helps ensure critical components remain within specification.

Daily checks should encompass rollers, slitting assemblies, and tension control hardware, with attention paid to wear patterns, bearing smoothness, and alignment accuracy. Applying lubrication at designated intervals reduces friction and thermal buildup, thereby extending the life of moving parts. Strategically replacing worn components before failure prevents production stoppages and avoids secondary damage to adjacent systems.

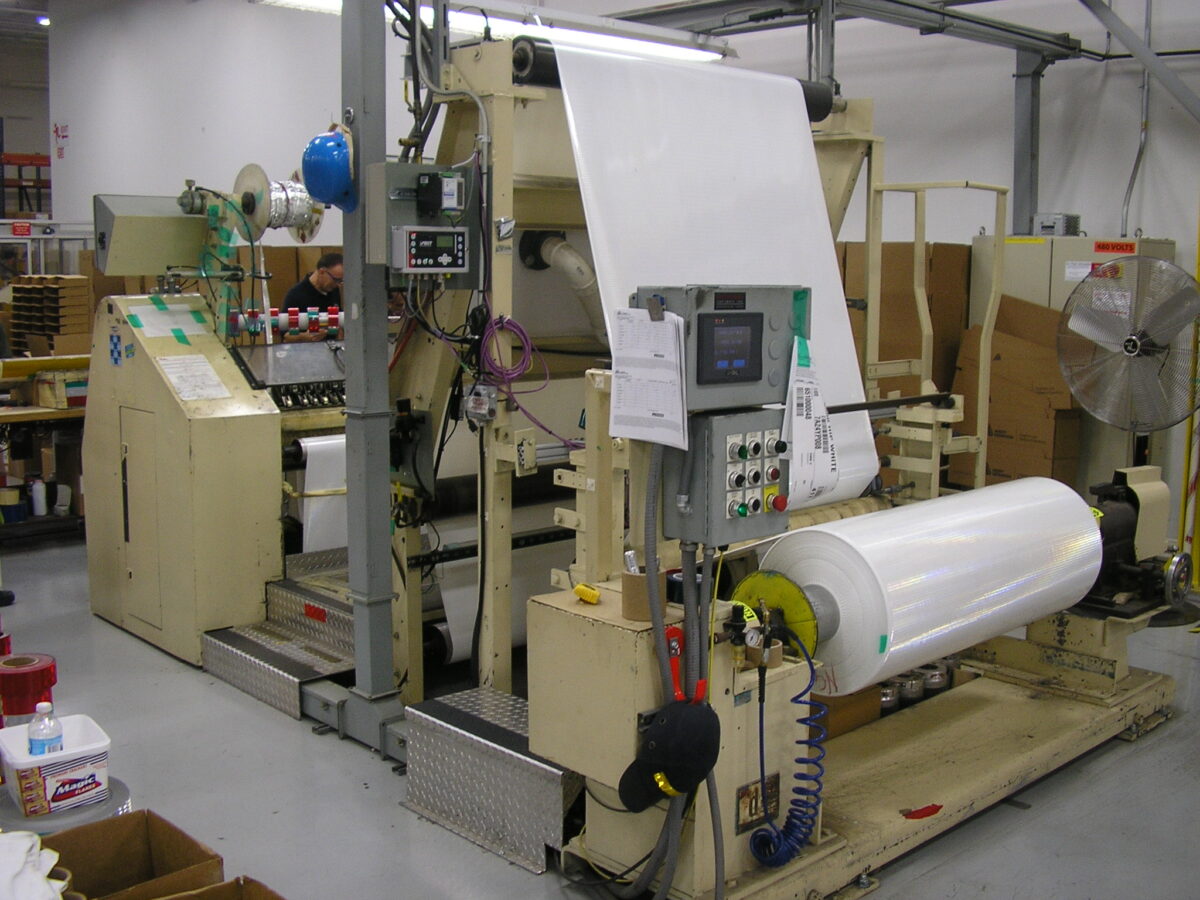

For operations looking to further extend equipment lifespan or enhance capability, rebuilding services present a cost-effective alternative to full replacement. These services often include the reconditioning of mechanical components, modernization of control platforms, and integration of automation technologies. By upgrading legacy systems with current-generation controls and user interfaces, businesses can improve diagnostic capabilities, enhance process repeatability, and reduce reliance on manual intervention. These improvements not only mitigate downtime risk but also align legacy equipment with modern production and safety standards.

Case Studies: Real-World Efficiency Improvements

Several real-world examples illustrate the measurable gains achievable through targeted surface winder optimization. A packaging manufacturer, for instance, improved material flow and reduced downtime by 30% through the adoption of a shaftless rewinding system, which eliminated the need for manual roll handling and simplified changeover processes. In another case, a paper converter enhanced product consistency and reduced trim waste by implementing servo-controlled shear slitting combined with automated blade positioning, ensuring optimal cut quality across varying material grades.

These examples underscore the value of investing in data-driven automation and precision control. They demonstrate how engineering-driven upgrades—when aligned with operator training and maintenance discipline—can produce quantifiable gains in efficiency, output, and quality assurance.

Emerging Trends in Surface Winder Technology

Technological advancements continue to drive improvements in surface winder efficiency. AI-driven automation is transforming the industry by enabling smart sensors and real-time analytics that enhance decision-making. Predictive maintenance solutions powered by AI help operators identify potential failures before they occur, reducing downtime and extending equipment life.

Energy efficiency is another growing focus, with newer surface winder models designed to consume less power while maintaining high performance. Improved roll handling systems are also emerging, reducing manual labor requirements and minimizing processing times through automated unloading and transport mechanisms.

As the converting industry evolves, businesses that invest in cutting-edge technology and proactive maintenance strategies will remain competitive and maximize their efficiency.

Conclusion

Achieving maximum efficiency with surface winders requires a combination of proper machine setup, regular maintenance, and leveraging advanced technologies. By focusing on optimizing material handling, refining slitting techniques, and maintaining precise tension control, businesses can enhance productivity and reduce operational costs. Implementing a proactive maintenance plan and considering equipment upgrades will ensure long-term success in high-speed converting operations. With the right technical and operational strategies, companies can ensure that their surface winders operate at peak performance—today and well into the future.